QuickBooks Manufacturing Software: 4 Integration Items to Consider

As ERP consultants, we run into examples all the time where QuickBooks is not an ideal solution for manufacturing for customers using QuickBooks out...

2 min read

Clients First, Texas Fri, Feb 14, 2014

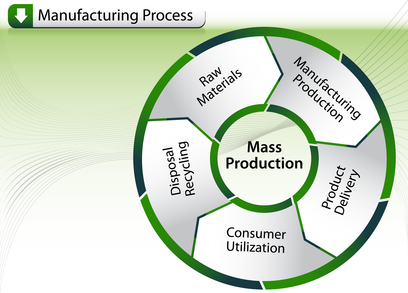

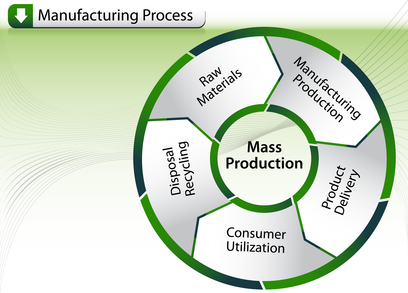

Running your business with the help of an advanced, fully integrated process manufacturing ERP solution, such as Dynamics NAV, is much better than opting for different software products that do not allow integration. Systems lacking integration prevent customization and optimization, negatively impacting the overall operation of an enterprise. As a result, that enterprise will be facing a series of hardships, which will prevent it from achieving its main purpose: serving and gratifying customers while making profits. Fortunately, this changes when an ERP solution is implemented.

Running your business with the help of an advanced, fully integrated process manufacturing ERP solution, such as Dynamics NAV, is much better than opting for different software products that do not allow integration. Systems lacking integration prevent customization and optimization, negatively impacting the overall operation of an enterprise. As a result, that enterprise will be facing a series of hardships, which will prevent it from achieving its main purpose: serving and gratifying customers while making profits. Fortunately, this changes when an ERP solution is implemented.

Since process manufacturing ERP solutions promoting long-term viability ensure business success, more and more organizations have decided to use ERP systems to support both current and future best practices. Here is how these solutions can help organizations operating within different industries.

An advanced process manufacturing ERP system, such as Dynamics AX, allows food processors not only to analyze and adjust recipes based on raw materials' characteristics; collect and record product details; control quality; manage inventory efficiently according to FIFO and LIFO procedures; check food process parameters; run batch analyses; track ingredients and foods by lot; and monitor the overall activity of production plants, but also to meet the FSMA requirements, which aim to ensure that food supply is safe.

Why do chemical manufacturing companies need a process manufacturing ERP solution? Simply because an ERP system ensures strong chemical manufacturing functionality, quality control, bidirectional lot traceability, shelf-life tracking and certificate of analysis (COA) generation, while making possible full compliance with the TSCA. Additionally, chemical processors can take advantage of procurement, inventory, warehouse, transportation, forecasting, financial and CRM tools to manage all their business areas. For more information on staying profitable as a chemical manufacturer, you can download the brochure below.

A process manufacturing ERP system could help these companies handle processes and assets across multiple plants; test procedures according to local and global regulations; manage resources efficiently; run operations in different currencies and languages; and get a complex accounting and financial solution, which facilitates authorization for expenditure, cost allocation, cash flow optimization, and gross and net reporting.

Typically complemented with robust tools, an ERP system especially built for paint and coating industry is able not only to develop formulas based on the properties of each chemical; manage and control numerous batches at the same time; track cost and inventory levels; perform cost analyses and forecasts; and help producers operate in a 'continuous flow' environment, but also to comply with federally regulated requirements, such as HASP, SARA and MSDS.

Production and distribution monitoring, quality control improvement, in-depth visibility into manufacturing processes, efficient stock control, accurate ingredient/product traceability, precise record keeping and regulatory compliance assurance are some of the things that a process manufacturing ERP solution intended for pharmaceutical industry can do.

Enabling interaction among procurement, manufacturing, stock and quality control, marketing and sales, a powerfully integrated ERP solution will unify all departments and functions across an enterprise in a single, standardized and useful format that can serve particular needs while keeping an eye on the big picture.

As ERP consultants, we run into examples all the time where QuickBooks is not an ideal solution for manufacturing for customers using QuickBooks out...

Microsoft Dynamics NAV 2017 –What’s New with Account Categories The latest release of Microsoft Dynamics NAV 2017 reinforces the commitment of...

When companies need IT business solutions, they turn to Microsoft in growing numbers. When organizations need IT business solutions, they turn to...