ERP Software Selection: 10 Important Questions to Ask Vendors and VAR

Top 10 ERP Software Questions to Ask when Interviewing Vendors and VARs Assuming you are involved in a for-profit enterprise, it doesn't really...

2 min read

Liz Gonzalez Tue, Mar 17, 2015

If you carry inventory in your warehouse operation business, you will eventually get to the point where you must do things a better way. You realize that the tools you have in place can’t keep up with your growing inventory tracking demands. The first thing you know you need to do if you have high levels of inventory turnover is get a robust warehouse management system. Doing inventory on paper, with an antiquated software system, or with a very basic ERP software or warehouse management system will no longer work for your growing business. There is one simple tool that is often overlooked in a warehouse that can bring such tremendous improvements: the RF (radio frequency) barcode scanning gun. So if you are in the market for a warehouse management system, don’t forget to ask about RF barcode scanning options.

Without a good warehouse management system, you have little to no control over what happens with your inventory. For example, if you need to ship an item and don’t have a good inventory control software system in place, you might ship the wrong item, or accidentally ship it twice. In inadequate because you have no way to watch what is occurring with your inventory. Or perhaps you’re experiencing a lot of shrinkage, but your employees are honest and just making honest mistakes, such as putting a book on the wrong shelf. A warehouse management system will keep you informed about where your inventory is at all times.

Before purchasing a warehouse management system, ensure that it utilizes RF (radio frequency) barcode scanning guns. A warehouse management system without RF guns still means that most activities continued to be performed manually: you get “x” item, it goes to “y” person, and you put that on a sheet of paper. The information on the paper needs to be typed into the computer – introducing a potential source of errors. The sheet of paper then goes with the item to the shipper and is sent out. RF guns are paperless, offer more control, and are more efficient because they allow you to scan a serial number or item number versus writing it down.

Here’s an example of using RF Guns in the process as an inventory picker:

You’re an inventory picker, you have an RF gun, and an order – the pick list – comes down to the warehouse. The pick list has the item, the quantity, and the location. Because you have an RF gun, it's paperless, so the pick list appears on the screen and shows you what you need to pick and where you can find it.

You might find the first item on the list in aisle 1 on shelf 13, or in row 15 on shelf 2, etc. When you go to the inventory location, you use the RF gun to scan the barcode on the shelf, which confirms that you've gone to the right place. You also scan the item to confirm you have the right item. The RF gun then moves on to the next item on the list, and you repeat the process until you complete your pick.

RF guns improve the process on the receiving end of a shipment as well. They make it easier to accept a delivery, move the items into inventory, and make transfers if necessary. The process uses the scanning gun to do the put-away process: the shipment comes in, you scan the barcode to enter the inventory into the system and to learn the shelf location. You can then have it moved to the correct location.

Good inventory management software that utilizes RF guns is the best way to get control of your inventory. You won't find the efficiency and superior level of control anywhere else.

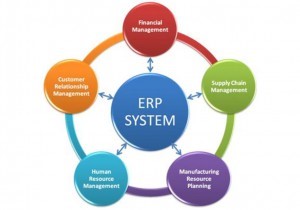

Historically, ERP software systems and access to the information to accomplish these goals were out of reach. But the right system is now within the budget of most small and mid-sized distributors and manufacturers. If you are considering different ways of improving your profitability, reducing your team’s workload, and improving your customer service, send us a message.

Top 10 ERP Software Questions to Ask when Interviewing Vendors and VARs Assuming you are involved in a for-profit enterprise, it doesn't really...

1 min read

Why Upgrade to an ERP Software System? Imagine you have a string that connects each employee and that string follows them all day long – you’d...

ERP Software Inventory Management Best Practices As ERP software consultants working with distribution companies over the past 30 years, we’ve...