2 min read

10 Ways Electrical Supply Distributors Optimize Inventory Processes

Implementing the proper electrical supply inventory optimization system can be as strategic and important to your bottom line as expanding your...

1 min read

Amjad Khan Fri, Nov 18, 2016

Many distributors rely on their manual internal business processes or software to help them decide when to replenish the inventory of stock products and how much of each product to reorder. They are relying on the system to alleviate customer service problems and improve profitability. Unfortunately we’ve found that often management and even buyers do not understand what the actual definition and purpose of each of the application’s parameters. As a result, the system is often setup incorrectly or misused and the distributor does not receive all of the possible value from their manual process or very expensive inventory management tool.

Over our years of experience implementing, training and servicing inventory management software we have learned the following 9 mistakes to avoid:About Optimize Our Inventory

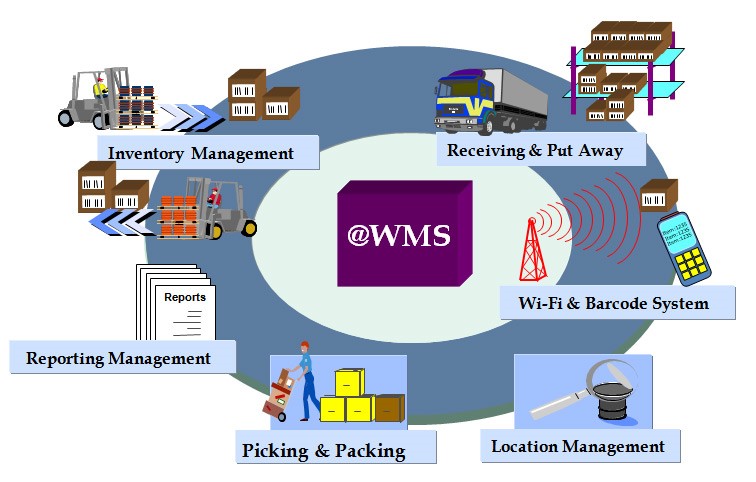

Established in 1988 and Headquartered in Orange County CA, Optimize Our Inventory is a division of aimINSIGHT Solutions, Inc. Our Vision is to serve the mid-sized Electrical Supply and Distribution companies as well as other Wholesale Distribution companies. We specialize in addressing and Bridging the Gap in technology. The goal of providing a Single Invoice, Single Shipment from multiple suppliers sources and Multiple Locations challenges that most Electrical Distributors face. Our team of consultants will visit you onsite and design the solution that fits your unique budget and challenges. We have worked with most of the off the shelf software available today. Our software solution and technology consulting is designed to “Bridge the Gap” that you face.

Recommended for you:

10 Automation Benefits of an Electrical Supply Inventory Optimization System

2 min read

Implementing the proper electrical supply inventory optimization system can be as strategic and important to your bottom line as expanding your...

1 min read

Improving the Accuracy of Your Electrical Supply Inventory Forecast Increased Competition. Competition continues to increase as new distribution...

An effective electrical supply inventory optimization inventory optimization system is a complex piece of software comprised of various modules that...