The ROI: Inventory Optimization for Electrical Supply Companies

An electrical supply inventory optimization system is designed to bring order and control to the warehouse, directing the efficient movement of goods...

2 min read

Amjad Khan Tue, Sep 20, 2016

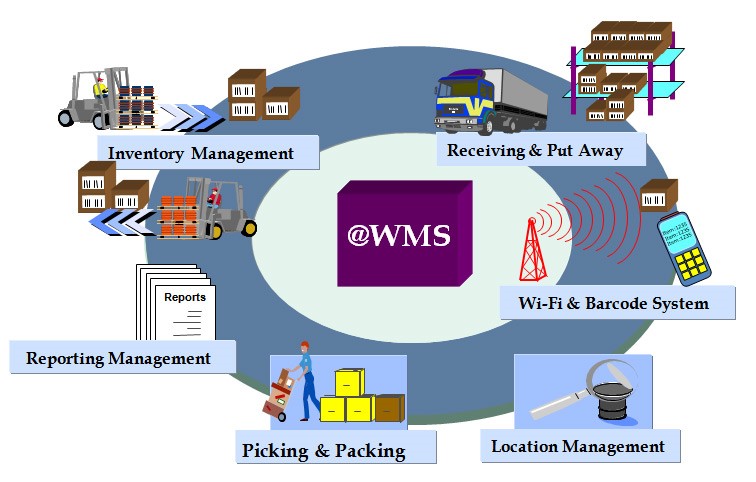

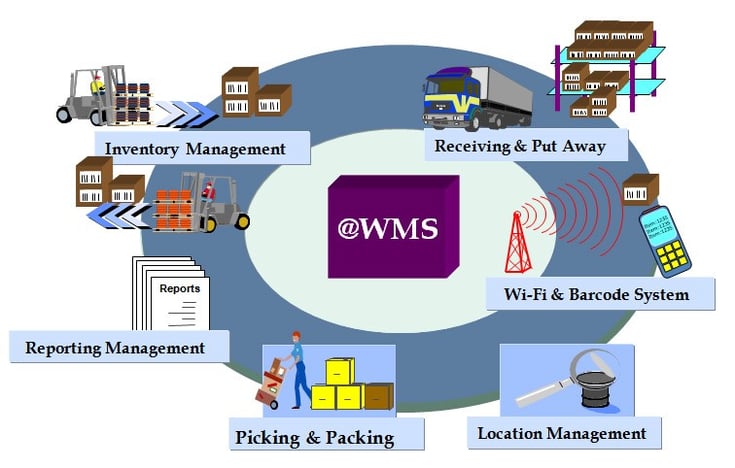

Receiving and Putaway - Inventory can be received by a purchase order, product or container. Multiple vendors per container are supported. Wave receiving allows individual receivers to process multiple purchase orders at the same time, and multiple receivers to work on the same purchase order simultaneously. ASN Receiving handles check-in against manifests.

Receiving and Putaway - Inventory can be received by a purchase order, product or container. Multiple vendors per container are supported. Wave receiving allows individual receivers to process multiple purchase orders at the same time, and multiple receivers to work on the same purchase order simultaneously. ASN Receiving handles check-in against manifests.

Inventory Control - Stock is allocated and rotated according to rules you configure, such as FIFO, LIFO, size, lot, serial number, expiry date, velocity and so on. Replenishment functions ensure that inventory is always available to fill orders, while demand management tools reduce your reliance on safety stock and allows for just-in-time purchasing. Electrical Supply Inventory Optimization System supports full inventory counts and recounts as well as incremental cycle counts, and provides the facility options to adjust physical inventory in or out of the warehouse.

Shipping – An electrical supply inventory optimization system weighs cartons and records shipment information, and uploads final costs and tracking numbers to ERP systems. Integration with your parcel shipping systems allows you to print compliant courier labels at any time during the fulfillment process. With a fully integrated shipping system, orders can be pre-rated and manifested before they are even released to the floor for picking.

Picking - Wave picking allows individual pickers to process several orders at a time, and to pack products directly into final shipping cartons – all in a single pass through the warehouse. Multiple pickers can also work on a single order simultaneously. An electrical supply inventory optimization system supports a dozen different styles of picking, including batch, product and zone picking, you can choose the optimal picking strategy for your warehouse layout.

Label and Document Printing – An electrical supply inventory optimization System automatically prints product labels, shipping labels, packslips, bills of lading, and other documentation, in conformance with manufacturing and shipping standards such as UPC/EAN, as well as various major retailers and shipping carriers’ formats. You can also create custom label types according to your client’s business requirements.

Order Management – An electrical supply inventory optimization system web dispatch (Web Browser Management Console) allows warehouse managers/supervisors to allocate orders according to predefined business criteria, and distribute orders to pickers according to optimal staff workloads and picking strategies. It supports various strategies of reserving stock to favored customers, sharing shortages by using the 'Fair Share' option across groups of orders and managing fill rates and backorders accordingly.

Kitting – An electrical supply inventory optimization system supports in-warehouse manufacturing, packaging and value-added operations. Finished goods assembled from subcomponent products may be built to stock, built to order, or simply picked as “eaches” (regular items). Kitting supports lot and serial visibility across the assembly process.

Customer Service - Using Web Dispatch, sales and customer service reps can verify the status of orders or inventory in real-time. They can also use Web Dispatch’s incidents module to notify warehouse staff of issues, assign tasks to specific users and follow up on resolutions.

Reporting- Web Dispatch provides dozens of pre-configured reports that monitor warehouse activities in real-time and compile historical and statistical data to help you measure warehouse performance, predict future demand, and re-engineer inventory storage and movement strategies. You can also generate custom reports and run database queries on the fly.

Technology - Running on Microsoft Windows and Microsoft SQL Server, Electrical Supply Inventory Optimization System is .NET compliant and web-services (SOAP) enabled. It supports a variety of Telnet- and Web-based portable devices and provides a rich set of browser-enabled dispatcher tools.

An electrical supply inventory optimization system is designed to bring order and control to the warehouse, directing the efficient movement of goods...

In today’s competitive marketplace, the primary focus of many electrical supply organizations is to reduce the costs associated with operations and...

2 min read

Implementing the proper electrical supply inventory optimization system can be as strategic and important to your bottom line as expanding your...