10 Workflow Benefits of an Electrical Supply Inventory Optimization System

An effective electrical supply inventory optimization inventory optimization system is a complex piece of software comprised of various modules that...

4 min read

Amjad Khan Wed, Sep 21, 2016

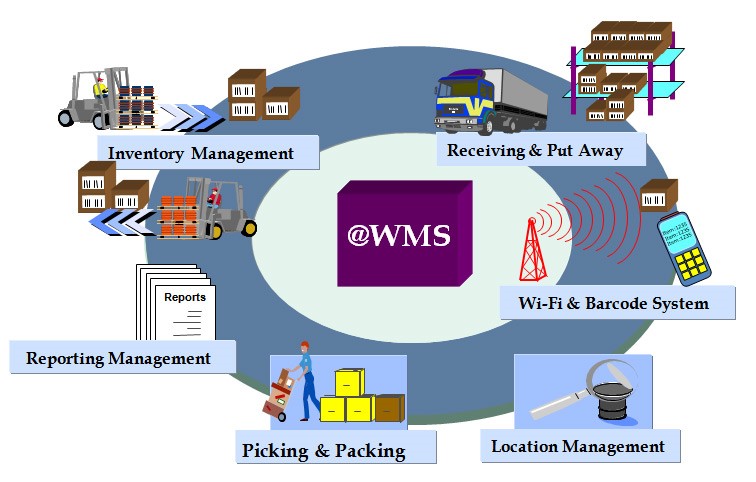

An electrical supply inventory optimization system is designed to bring order and control to the warehouse, directing the efficient movement of goods and labor, in turn reducing costs and improving customer service. Inventory accuracy is the key to maintaining an efficient warehouse and avoiding poor productivity, poor purchasing practices and poor customer service. An inventory optimization system offers a solution that ensures companies know what they have and where they have it in real time.

An electrical supply inventory optimization system is designed to bring order and control to the warehouse, directing the efficient movement of goods and labor, in turn reducing costs and improving customer service. Inventory accuracy is the key to maintaining an efficient warehouse and avoiding poor productivity, poor purchasing practices and poor customer service. An inventory optimization system offers a solution that ensures companies know what they have and where they have it in real time.

An electrical supply inventory optimization system also allows for the development of efficient procedures for completing daily tasks that are used to create audit trails for productivity tracking. These audit trails enable companies to perform two very important management functions:

An electrical supply inventory optimization system increases operator accountability and improves management control so managers are free to focus their efforts on warehouse improvements rather than on dealing with unwarranted emergencies.

An electrical supply inventory optimization system increases operator accountability and improves management control so managers are free to focus their efforts on warehouse improvements rather than on dealing with unwarranted emergencies.

An inventory optimization system also decreases training time and reduces overall training costs. This self-checking, intelligent system enables new employees or temporary workers to work productively without extensive product knowledge.

For the purpose of an example, we will assume that a company is shipping 250 orders (around 600 cartons) a day, pays an average of $10 per carton for freight and has fully-burdened labor costs of $20 an hour. In a manual or disconnected warehouse operation, typically it takes 30 keystrokes to ship a carton and update the host computer. If we multiply that by 600 cartons a day, that comes to 18,000 keystrokes a day, multiplied by 22 working days a month, equals an astounding 396,000 keystrokes! If we assume one error for every 800 keystrokes, a 0.12% possibility, we would find 495 errors per month or about 23 per day approximately 4% of the total daily shipments.

In a warehousing setup, a mistake can typically mean that a wrong product was sent and has to be picked up again; and normally the company shipping the product pays that expense. Additionally, it includes the cost to reship the correct product, and many times there is the added expense of expedited freight to keep your client happy. Plus, let’s not forget the cost of administrative time to change and correct the invoices. Clearly, errors are easily a $50 cost each. So, even if we are extremely conservative, and use only 7 errors a day as significant, (which is 98.83% accuracy) at $50 each, our costs come to $350 a day; multiplied by 22 working days, $7,700 a month and $92,400 per year. This alone can justify the investment in An inventory optimization system.

Next, let’s consider the direct saving in labor gained from eliminating the manual rekeying of data in the accounting department. Ask your accounting clerk how long it takes to type in the freight charges, the 18 character alphanumeric tracking number, other data, and the keystrokes necessary to complete the order. Let’s say it takes one minute per order, multiplied by 250 orders or 4.2 hours a day. This is assuming that this clerk types non-stop and does not take a single break or gets interrupted. At a labor rate of $20/hr with benefits, multiplied by 4.2 hours, we have a total labor expense of $84 a day, $1,848 a month and an additional $22,176 a year. An inventory optimization system linked to the shipping system can cut labor costs significantly and pay for itself over and over again.

Another area where we can reduce labor costs is customer service. Find out how many times you receive inquiries about the status of shipments. How much time do you spend researching such inquiries? Let’s say that 10% of your shipments trigger a phone call and you get 25 per day. If you spend 10 minutes on each one, you are spending 250 minutes x 22 workdays or 5,500 minutes/month, which comes to 92 hours a month. At $20/hr that equals $1,840 a month or $22,080 a year.

An inventory optimization system linked with an integrated EDI system, can automate the process of notifying the customers of the shipments through Advance Ship Notices (ASNs) and significantly reduces the number of calls received for shipment status. Using EDI-based communication also reduces the collection time for receivables. If at any time, you have $1 million of receivables, collecting them 5 working days earlier will have significant impact on cash flow. Further, you no longer need to send paper-based invoices to the customer. At 250 shipments a day x $.37 (for the postage), you would save $93 a day or $2,046 a month ($24,552 per year). This, too, goes right to the bottom line. Most large retailers are requiring their suppliers to accept EDI transactions for orders and advance ship notifications. In case of shipping errors, backordered items or the absence of complete documentation, including shipping labels, contents lists, packing lists, ASNs, and so forth, a customer might bill back with a penalty and “charge back,” as much as $500 per order. If out of the above-mentioned 7 errors in a day, 2 of the errors were with those customers who transact using EDI and the “charge back” on these two orders was $100, our costs will come to $2,200 per month and $26,400 per year.

Another area where an electrical supply inventory optimization system saves money is in the inventory management arena. Let’s assume your company loses $300 worth of inventory items every month through shrinkage, damage, misplacement or the “unknown.” These lost materials must be replaced with profit dollars, assuming your distribution profit margins are 6%. To cover the loss of $300, you must sell an extra $5,000 each month or $60,000 annually. This puts an additional burden on any salesperson. With RF-driven perpetual cycle counts and inventory movement control, you can achieve up to 99.99% accurate inventory information. Companies often find themselves taking orders and making promises that they cannot deliver. When the back office is not in sync with the warehouse operations, and when the inventory information is not accurate, some customer orders remain backordered, fully or partially. Someone then has to make the painful call to advise the expectant customer of the discrepancy and make the necessary adjustment. This can affect future sales prospects for those customers.

Further, with 99.99% accuracy, you will need to book fewer expenses in inventory write-offs at the end of the year, once again positively affecting the bottom line.

Improvement in work efficiencies is yet another benefit that An inventory optimization system helps achieve. The directed movement of pickers through aisles, simultaneous input of data, real-time validation and accurate location positioning of items (pickers never go to an empty bin, never wonder if some quantity is available in the overhead bin, and so forth.) all contribute to quicker, easier, and hassle-free picking process in the warehouse, thereby increasing the efficiency and productivity of the warehouse staff.

With increased work efficiencies, companies can benefit from fewer staff to maintain the same shipping volume. In other words, companies can either reduce cost or use the existing staff to expand business to higher volumes and hence higher revenues. Fewer staff would also mean buying and maintaining less warehouse equipment such a forklifts, RF handhelds, and so forth. All these savings can positively affect the bottom line.

An effective electrical supply inventory optimization inventory optimization system is a complex piece of software comprised of various modules that...

In today’s competitive marketplace, the primary focus of many electrical supply organizations is to reduce the costs associated with operations and...

1 min read

Electrical supply distribution is a competitive business. Many distributors rely on their manual internal business processes or software to help them...