Getting Started On A 5S Implementation, pt. 2

This is part 2 of our series on 5S implementation. In part one, we talked about getting everyone on the same page about the implementation alongside...

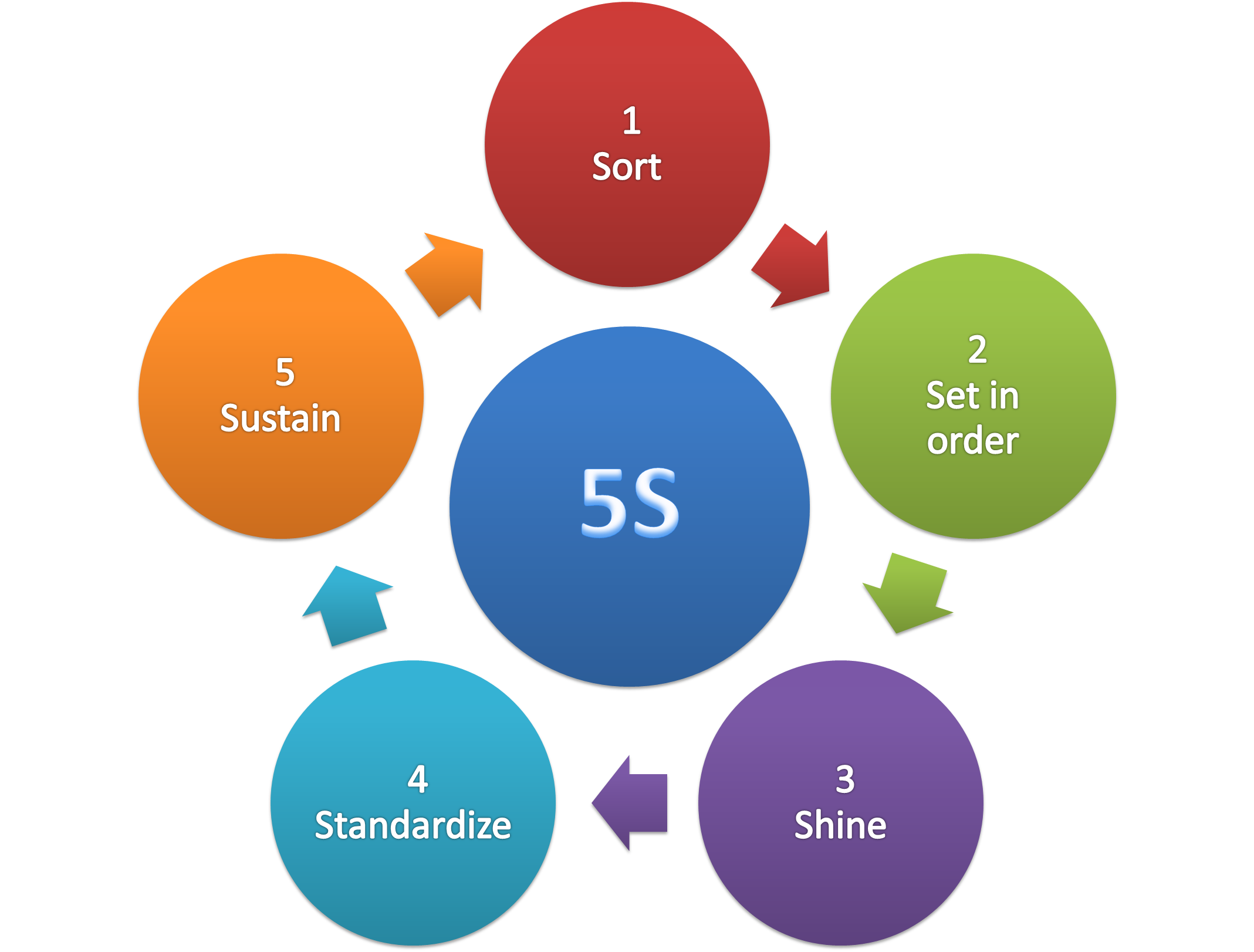

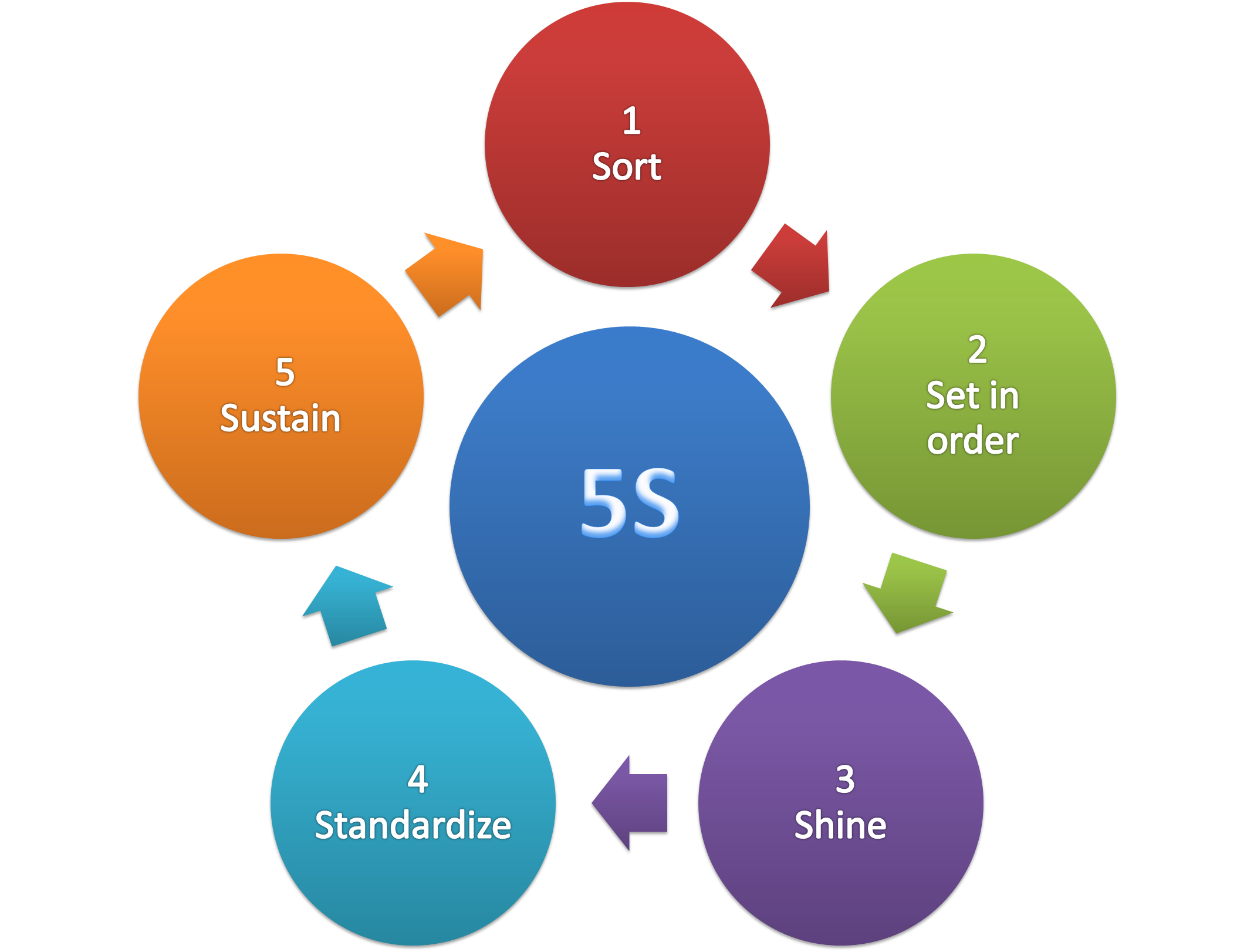

You might have read our article explaining what is 5S along with its benefits. If you didn’t I suggest you check it out before reading this article, because we will be going a step further by discussing what the best practices are for implementing 5S in your warehouse.

Whenever you’re trying to implement anything into an organization, there will be debate coming from all sides: from the "what", to the "when" and "how" things should and shouldn’t be done. The fact is that you can’t please everybody, but what you can do is keep all levels informed of the pending changes and generate some excitement about the benefits of the transition.

Promote at all levels-It is important that the managers who will be implementing 5S are informed of the change at the soonest convenience. Of course, there may be some nay-sayers that won’t like being told that their routine will be changed for a few months to include organizational tasks. To combat this, it is ideal to start a campaign that walks your staff members through the process, how it will affect their normal job function, and how the results will benefit them as an employee as well as the company as a whole.

Give a real-life example- A great way to get your employees to warm up to the idea of starting a major cleaning process is to give them an idea of what they will be doing with this process. For example, have them implement 5S in an office or a break room. Somewhere they can get a good feel for what they will be doing when they implement the process on a full scale. By the end of this exercise they should at the very least have an understanding of the process, what the end results should look like and be able to see the tangible benefits implementing 5S will produce.

As you already know, it is essential that all implementation is given a timeline and flexible deadline. It can be difficult to find the balance between giving a fair amount of time and encouraging a fast 5S implementation. Another thing to consider when making this decision is that your company will not be stopping normal operations, so be sure enough time is allocated for both jobs.

Give it some time- Choose a start and end date for the process that both gives a sense of urgency but doesn’t add unnecessary pressure that will guarantee a sloppy job or cause overtime. Unless you have a small facility, you should probably be thinking a few months and not a few weeks. As soon as a reasonable time frame is finalized it is ideal to inform your operations team so they can plan ahead and be mentally ready when the time comes.

Provide implementation guidelines- It is best to not just give them beginning and ending dates but also give time a general plan and time frame for every stage of the implementation. This is a great way to communicate the corporate vision for the implementation as well as to give your operations team some guidance. Just to be clear, these guidelines should not be enforced as mandatory regulation because your subordinates have already been left out of in the decision to implement 5S. If they are forced to do each step the way you want it done, then it could create an unnecessary “upper-lower” conflict. Your message should be more like, "This is the official end date and we came up with a guideline to help you get back to regular operations as soon as possible". By giving your employees the ability to carry the plan out, you might be surprised at how many of your guidelines they will follow on their own, and better yet have superior ideas on how to improve organization in their own workspaces.

Stay tuned for more tips and best practices for implementing 5S in the upcoming weeks.

Clients First is an expert at implementing Acumatica, Dynamics AX and Dynamics 365 (which also made it into the leader quadrant). Contact our sales team today by calling 800.331.8382 or emailing info@clientsfirst-tx.com. Clients First implements and supports clients across the U.S.A. and in 11 countries. Our team of professionals are ready to help implement the best finance and operations solutions for manufacturers, distributors, project-based manufacturers, MRO (maintenance, repair and overhaul), and professional services.

Source: Industry Week

This is part 2 of our series on 5S implementation. In part one, we talked about getting everyone on the same page about the implementation alongside...

This is our third and final installment of our series on 5S implementation. If you haven't already, take the time to read it from the beginning...

If you’re a manufacturer that’s looking to cut some of the fat that might be weighing your business down, you’re not alone. In this article, we will...