Production Scheduling Software - 3 Steps to Set Up a Master Production Schedule in Acumatica

Production Scheduling Softwarein the Acumatica Manufacturing Edition – Master Production Schedule (MPS) The new production scheduling software...

3 min read

Art Olsen Wed, Oct 25, 2017

How to Forecast with Production Scheduling Software

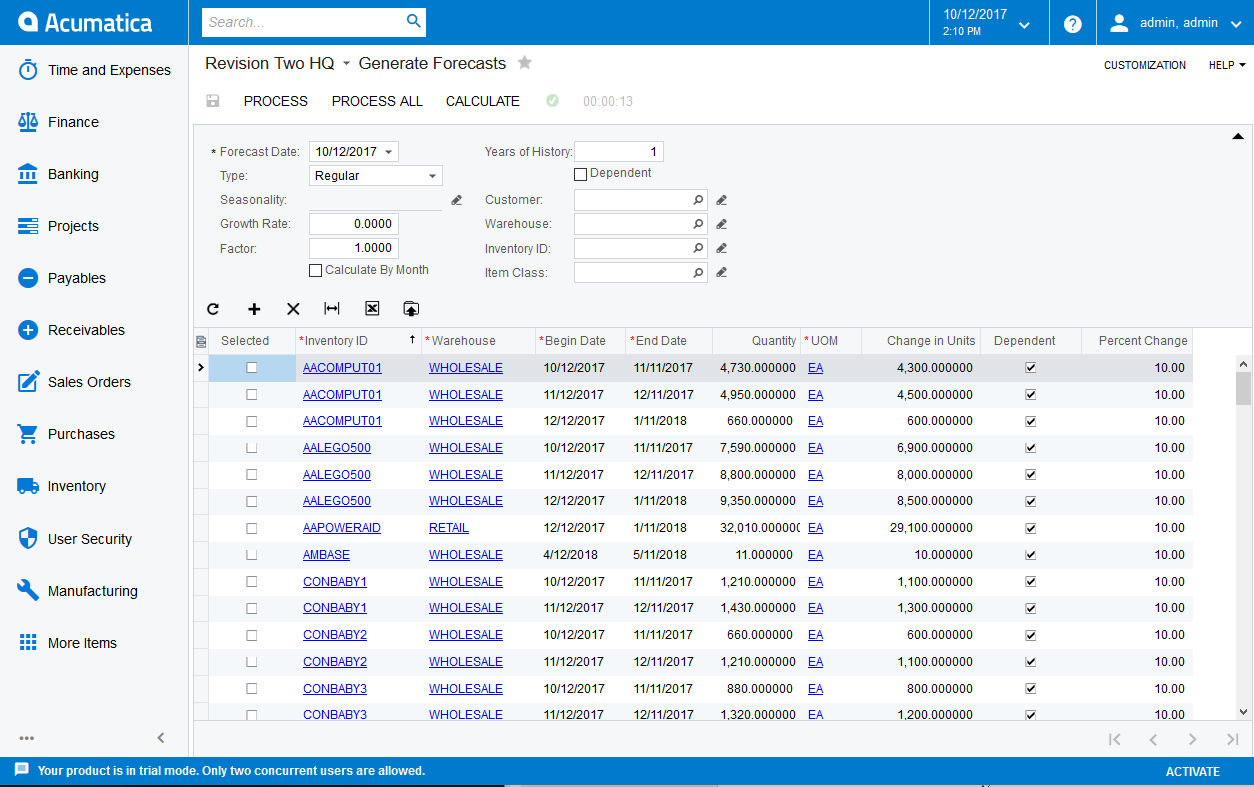

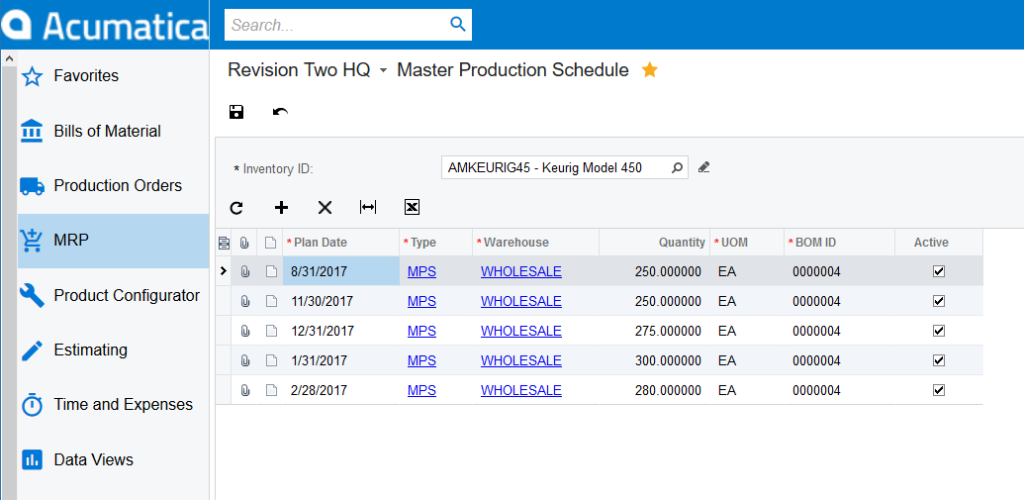

How to Forecast with Production Scheduling SoftwareForecasting with production scheduling software helps manufacturers control how much is produced in response to customer demand. The forecasting capabilities in the new 2017 R2 Acumatica Cloud ERP Manufacturing Edition (formerly known as JAMS) help manufacturers manage the order-to-production-to-cash process. Since there are two different ways to set up forecasting, we’ll cover the first process in this article and the second process in another article. First, we’ll walk you through eight steps to generate a sales forecast of end items to sell. Our follow-up article will cover the second approach which is how to create a master production plan.

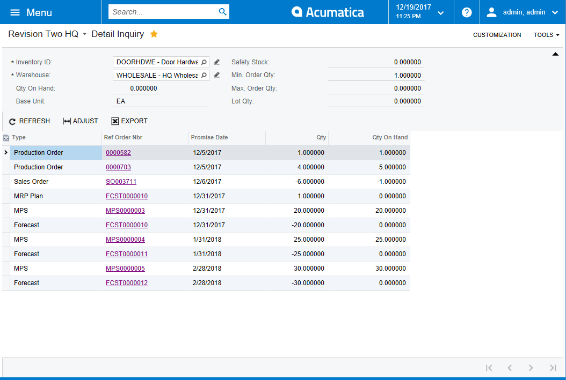

The capabilities in the 2017 R2 Acumatica Manufacturing Edition enables you to generate a 12-month sales forecast based on actual sales history. The Acumatica production scheduling software then uses this sales forecast to create a production plan and a purchasing plan. The system generates automatic messages to purchase components and produce products to meet the forecast demands.

This is the first step in taking full advantage of the production scheduling software features in the new Acumatica Manufacturing Edition. We will cover more helpful tips in the manufacturing process in following posts to help you get the most out of your Acumatica investment.

To learn more about Acumatica and it's production scheduling software and forecasting functionality, click here:

This whitepaper will help you get prepared for a successful cloud ERP implementation. These questions have been developed by our ERP consultants who are industry experts in helping small to medium-sized businesses overcome challenges with technology.

Stratotech Partners, LLC. - Headquartered in Seattle, Washington, Stratotech serves Acumatica customers in the Seattle metropolitan area and northwest region. Stratotech's expertise allows them to focus on small to mid-sized manufacturing companies who are outgrowing existing systems and looking for lower cost cloud-based alternatives. Stratotech is a certified Acumatica cloud ERP and Smartsheet provider. These are leading cloud platforms for collaboration and project management.

Stratotech Partners, LLC is an Acumatica Value Added Reseller (VAR) partner. Our experienced consultants provide cloud-based business management software to enable small and mid-sized companies to accelerate their businesses. Acumatica is built on modern cloud and mobile technology and has a unique customer-centric licensing model. Our specialties include business management applications such as Financials, Distribution, CRM, and Project Accounting, on a robust and flexible platform.

For more information, please visit our website, call 206-336-9197 or email us.

Follow us on Facebook, LinkedIn, Google+ and Twitter!

Another version of this blog was previously published on 10/25/17 - Acumatica Production Scheduling Software - Creating a Forecast

Production Scheduling Softwarein the Acumatica Manufacturing Edition – Master Production Schedule (MPS) The new production scheduling software...

Acumatica Manufacturing Consultant Reviews Accurate Planning with Acumatica Manufacturing Edition Acumatica Manufacturing Edition (AME)* with its new...

5 Essential Microsoft Dynamics NAV Manufacturing Capabilities In order to understand how Microsoft Dynamics NAV manufacturing capabilities can help...