Warehouse Management Systems (WMS) and Zone Picking Basics

Warehouse Management Systems (WMS) – Two Types of Zone Picking and the Basics Today’s distribution centers (DC) understand the importance of...

3 min read

Greg Miles Wed, Aug 03, 2016

Discrete Picking and Your Warehouse Management System (WMS)

Discrete Picking and Your Warehouse Management System (WMS)As your business grows, maintaining productivity while also keeping accurate inventory counts and reliable fulfillment are common challenges in today’s distribution centers (DC). It’s important to know if you are picking in the most effective order and more importantly, picking the order in the right way. If you are a multi-channel fulfillment company like Amazon, your picking methods become more important as a determinant in the overall productivity of your operations.

In a discrete pick, the operator is directed to each bin in sequence, and told the product, pack size, and quantity to pick. The required products for each order are picked then scanned with its barcode label. The appropriate carton number is then provided to pack the product. The items are then placed into this carton and the label is scanned for that carton. Finally, the quantity of the product that was picked is entered in the warehouse management system. The warehouse operator is then directed to the next order to pick and the process is repeated until you have picked and packed the complete order.

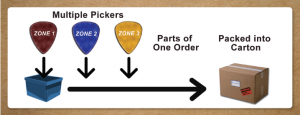

For picking large discrete orders you can reduce the order cycle time (increase throughput) by assigning multiple operators to a pick. This can be accomplished by splitting up the order picks by aisle or area where different operators pick the items in a specific aisle or area (see our Zone Picking article). Alternatively, operators will work in the same area but start at opposite ends to eventually meet in the middle when the order is complete. This is supported by a concept referred to as Reverse Picking.

Learn more about Warehouse Management Systems Functionality

Posted by iCepts Technology Group, Inc. An Accelos and Microsoft Dynamics NAV Partner in PennsylvaniaAbout iCepts Technology Group, Inc. Middletown, PA

We are a Microsoft Dynamics NAV Partner offering implementation, service, and support for Microsoft Dynamics NAV in: PA, DC, DE, MD, NC, NJ, NY, OH, VA, WV, and the entire Mid-Atlantic Region. We also offer implementation, service, and support for Accellos One Warehouse Management Systems in: PA, DC, DE, MD, NC, NJ, NY, OH, VA, WV, and the entire Mid-Atlantic Region.

As experienced SCM, WMS and ERP consultants and value added resellers (VARs), we provide start to finish services for the solutions we represent Microsoft Dynamics NAV for Distribution and Manufacturing, Accellos Warehouse Management System (WMS), Server virtualization, open source VOIP phone systems and infrastructure and security. We provide services that cover process analysis, implementation, training, security and networking. Naturally, we also provide full ongoing support for years after implementation to help our clients succeed. We are your one stop shop for your business technology needs.

Contact us for additional information by clicking HERE or...

Phone: 717.704.1000

Email: info@icepts.com

Another version of this article was previously posted by iCepts Technology Group, Inc.- A Pennsylvania Microsoft Dynamics NAV Reseller on July 27th,2016 http://www.icepts.com/warehouse-management-basics-discrete-picking/

Warehouse Management Systems (WMS) – Two Types of Zone Picking and the Basics Today’s distribution centers (DC) understand the importance of...

The Basics of Wave Picking and Warehouse Management Systems (WMS) Every distribution company knows the importance of operational efficiency when it...

Did you know there is more than one way to ship a box? If you are in the business of pick, pack and shipping, you may find this blog series useful to...