Is your organization “all in” for service? Determine whether your ERP software alone for field service management is enough to be successful.

Is your organization “all in” for service? Determine whether your ERP software alone for field service management is enough to be successful.

In the last decade, horizontal enterprise resource planning (ERP) systems have grown in breadth of functionality and range of customizability as companies of various needs and industries adapt them for their daily business operations. Indeed, high functioning ERP systems can go beyond just number crunching to include features like purchasing, invoice generation, and inventory management.

Some horizontal ERP systems even offer industry-specific modules, like a field service module, that expand how customers can use the software. With a field service specific add-on, some service organizations are exploring how they might adapt an integrated ERP system to manage all their field service needs.

While this integrated ERP and field service set-up sounds appealing, service is an industry that asks a lot of its software. So before you make any important software decisions, you may want to ask yourself whether an ERP system, even with a field service management add-on, is enough. We explore the pros and cons of using ERP software for managing service.

Pros: Where ERP tools can help an organization manage field service operations

ERP systems now play a larger role than ever for companies in a variety of industries, including today’s field service organizations that benefit from several customizable and integrated ERP features. Here we’ve listed some Pros of using an ERP system for service management:

- Accounting and General Ledger (GL): Nearly every organized company today uses some sort of ERP system for accounting. Accounting is ERP software’s specialty, and it’s also obviously a field service need. With ERP software, field service organizations can see where their money’s going, where it’s coming from, and balance it, making decisions based on that financial information. Companies can add modules to the basic system, including accounts payable, accounts receivable, and GL, which track every revenue stream in or out of the organization. For service work, it’s essential that managers can monitor where their highest revenue sources are and make sure they’re making more than they’re spending. ERP systems do that revenue tracking for them, stabilizing the company’s financial status.

- Purchase Orders/ Sales Order System: When companies sell equipment or service, ERP systems can create the sales order and produce a receipt for the customer. The system then schedules the order, but, as we’ll see later in the “Cons” section, ERP scheduling is not nearly precise enough to meet the needs of a competitive field service organization.

- Inventory Management: Managing inventory is another important task ERP systems can perform for service organizations. Purchase orders entered into the system flow into inventory, alerting the right people of what parts are needed for each sale. Since ERP inventory management is generally used for sales rather than service, however, some of the visibility necessary for performing service tasks, like access to parts in technician vans, isn’t perfect.

- Customer Information: ERP systems manage customer information, including contact information and sales history, which is useful for organizations selling equipment. Service needs, however, require additional customer documentation, so, if you’re doing service in addition to sales, you might need an additional integration to add information that wouldn’t be relevant in an ERP system alone.

- Invoice Generation: When orders come in, ERP systems can create detailed invoices to send directly to customers. A service invoice is created by printing the sales order, giving it to a technician who records his hours and work, then the invoice is generated based on billable labor and parts.

- User Defined Fields: One reason service organizations try to adapt ERP systems to manage their service needs is because user defined fields allow them to create fields for processes that aren’t originally included in the ERP system. For service, companies can create custom fields for capturing field service business information, for example. These user defined fields, adapted for a company’s specific needs, can be useful for organizations in which service isn’t their main priority. It’s important to remember, however, that these add-ons won’t be as functional as a“best-of-breed” system created specifically for field service.

Cons: Where ERP software typically struggles to meet field service needs

While ERP systems can perform some service needs, and user defined fields and add-ons contribute additional service management functionality, some processes can’t be accomplished through ERP software. Here are some of the “Cons” of attempting to use an ERP system for all your service processes:

- Contracts management: Contracts management is the core of service management. From managing the right contacts and customer information to processing, scheduling, and billing work orders, managing contracts is what makes a service organization tick. With service work orders and contracts, you need to be able to track not only parts, but also warranty, labor, preventative maintenance, service level agreements (SLAs) renewals, scheduling, etc. Without the ability to perform these functions and perform them well, it will be nearly impossible to succeed in an ever more competitive service world.

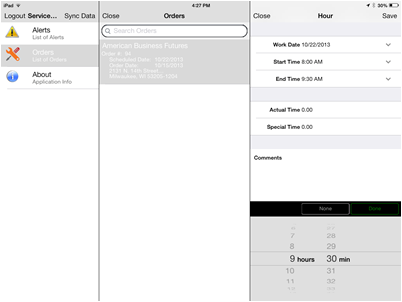

- Mobile for field technicians: ERP systems are designed to serve businesses that exist within the confines of a building. And in their defense, most businesses and ERP users do work within four walls. Field service, however, inherently does not, which is why it’s so important for service organizations to have high functioning mobile software that’s run natively and works offline. Most ERP systems do not offer mobile and those that do, aren’t as well supported or complete as a mobile application built and supported specifically for field service. Without mobile, field service workers are missing the key component that connects field work with the rest of the system, leaving them at a disadvantage for achieving field service success.

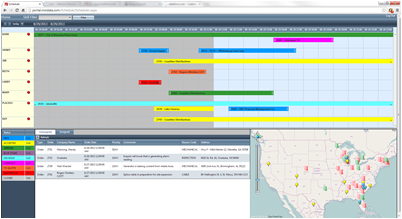

- Technician resource scheduling: While ERP systems can perform general scheduling tasks like booking an installation date after a purchase order comes through, its functionality is nowhere near the level that’s needed to efficiently schedule technicians in the field and stay competitive in the service industry. For example, there’s no data to allow the scheduler to filter by skill-set, location, or availability. Scheduling in an ERP system says nothing about service timelines and provides no insight into tech status or location. If you’re serious about service, the lack of advance scheduling in ERP systems will make it difficult to keep up with customers’ expectations of short arrival windows and high first-time fix rates.

- History for customer-owned equipment: ERP systems can handle inventory on hand and how many parts are spoken for, but they don’t have visibility into equipment history or needs. Technicians can’t see important equipment information to keep their customers informed or make crucial preventive maintenance contract sales. With an FSM system, techs can provide advice based on equipment information that they wouldn’t be able to do without being able to see the equipment’s history.

- Asset tracking/warranty information: Similar to the lack of equipment history, ERP systems don’t have a way to track asset and warranty information for equipment. ERP software knows when the part was bought, but techs can’t tell if it’s under warranty. When techs don’t know information about the assets or have up-to-date warranty information, the quoting process slows and can lead to errors in billing. These errors can not only hurt the service business’s bottom line, but they can also damage customer relationships by billing customers incorrectly or not repairing something covered under warranty.

- Labor-based quoting: When technicians are using mobile technology in the field that syncs with the back office, their labor automatically syncs with the work order when they update it on mobile device. Labor then integrates with payroll and creates labor-based quoting for billing customers. ERP systems aren’t made with service labor capabilities, so it’s difficult to factor labor costs into the quote.

- Granular performance analysis based on accounting statement: Because of the variety of service types and workers performing jobs in a range of environments, it’s important to be able to analyze service data on a granular level. ERP systems don’t allow for utilization analysis, which makes it difficult for service organizations to determine where their revenue is coming from, where they need to improve, and what they’re doing well. FSM systems can drive GL account distributions based on many factors, such as type of job, division, line of business, etc. With this information, you can make business decisions like where you want to focus and spend more resources in the future. Since these measurements are driven by a certain type of work, it’s difficult to distinguish those differences to measure utilization in an ERP system.

Field service is a customer-centric industry. Therefore, the software service organizations use needs to be created and run with people in mind. While ERP systems are useful accounting and business management tools, they’re generally focused on dollars, not people. This difference in focus and priority is the major distinguishing factor between FSM and ERP systems and should help you decide whether an ERP system is enough to manage such a valuable entity of your organization, like service.

Conclusion: Don’t settle for what’s convenient

Which would you use to pull your dogsled: team of well-trained huskies or a team of miniature poodles? Sure, if you had enough poodles and the sled was light enough, you might be able to get the sled from point A to point B. But wouldn’t it be wiser to invest in the huskies to pull your sled quickly and efficiently every time? Similarly, if you consider yourself a service organization, you shouldn’t be treating your service processes as second rate. Service, when done well, can be a huge profit center for organizations in a variety of industries from construction to HVAC to equipment distribution. But in order for service to be done well, you need to have the best tools available to make it run like clockwork, keeping customers happy and operations and employees productive.

It’s important to keep in mind that field service modules for ERP systems are just that: modules. They don’t have the full functionality, accuracy, or specialization of a “best-in-breed” system created specifically for field service. If you want to be taken seriously as a service organization—if you want a team of huskies pulling your sled—service management software is not something you want to skimp on. By settling for what’s convenient, like a field service add-on or managing your service needs through an ERP system, you risk running a service organization that’s only mediocre at managing service.

Like this post? Subscribe to our Field Service Management Blog for original weekly content updates.

Add mobile apps to your enterprise software offerings by partnering with a field service software provider.

Add mobile apps to your enterprise software offerings by partnering with a field service software provider.

.png?width=217&height=155&name=service_management_software_home_(2).png)