Process Manufacturing Software: Manage Yield, Scrap Other Factors

The choice to implement process manufacturing software is typically a necessity for process manufacturing enterprises due to the nature of the...

2 min read

Gustavo Zientek Fri, Feb 20, 2015

Top 10 Checklist

As a process manufacturer, depending on the level of your business complexity and sophistication driven by customers, product, industry and regulatory compliance, an additional solution is often required to cover your specific industry requirements. The process manufacturing software system we sell and support is ProcessForce, which works with small and medium-sized process manufacturers. If you have questions about selecting the best ERP system to fit your unique process manufacturing software requirements, VISIT OUR WEBSITE www.consultare.net, EMAIL US at info@consultare.net or CALL US at 786-220-4300. We will help evaluate your requirements with a free needs assessment.

Consultare is an SAP Business One partner with extensive knowledge and experience in the implementation of business systems. We help our customers to manage their companies more efficiently, utilize their resources better and obtain better and faster information out of their systems, by implementing “Best in Class” solutions specifically designed for the small and medium size business.

Our focus is in providing value added to companies that require industry solutions to manage their operations. We implement industry solutions from worldwide-renowned Gold SAP Partners. Our ERP consultants focus in Process Manufacturing, Data Collection, MRO, Equipment and Machinery Rental, Warehouse Management Systems and Tools that provide value added to SAP Business One Implementations. We cater to many industries but specialize with proven success in food and beverage, live sciences, pharmaceutical, plastics and chemicals. All solutions are SAP Certified. We are headquartered in Miami, FL with offices Buenos Aires, Argentina.

Another version of this blog was previously posted on February 15, 2014 on Consultare’s BLOG “Top 10 ERP Requirements for Process Manufacturers”

RELATED ARTICLES:

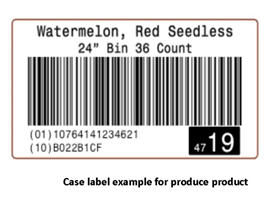

Process Manufacturing Software: PTI Compliance with SAP Business One

Process Manufacturing Software: Manage Yield, Scrap Other Factors

Photo courtesy of www.freedigitalphotos.net by stuart miles

The choice to implement process manufacturing software is typically a necessity for process manufacturing enterprises due to the nature of the...

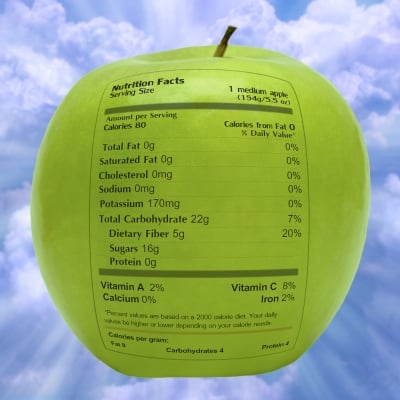

Process Manufacturing Software Integration with Nutrient Labeling – DV and %DV If you are a food or beverage process manufacturer, you are aware of...

Process Manufacturing Software and PTI Compliance: SAP Business One Prints PTI Compliant Labels As a process manufacturing business, you are well...